IN PROGRESS! Updating this page as I detail the designs over the weekend. Design worksheets are constantly in flux, so what I have posted here is a “snapshot” of each worksheet.

In this post I start with an overall summary of the machine, followed by a discussion of each module along with the calculations I did to support my design decisions. Any mistakes I made, are here for the world to see!

Machine summary

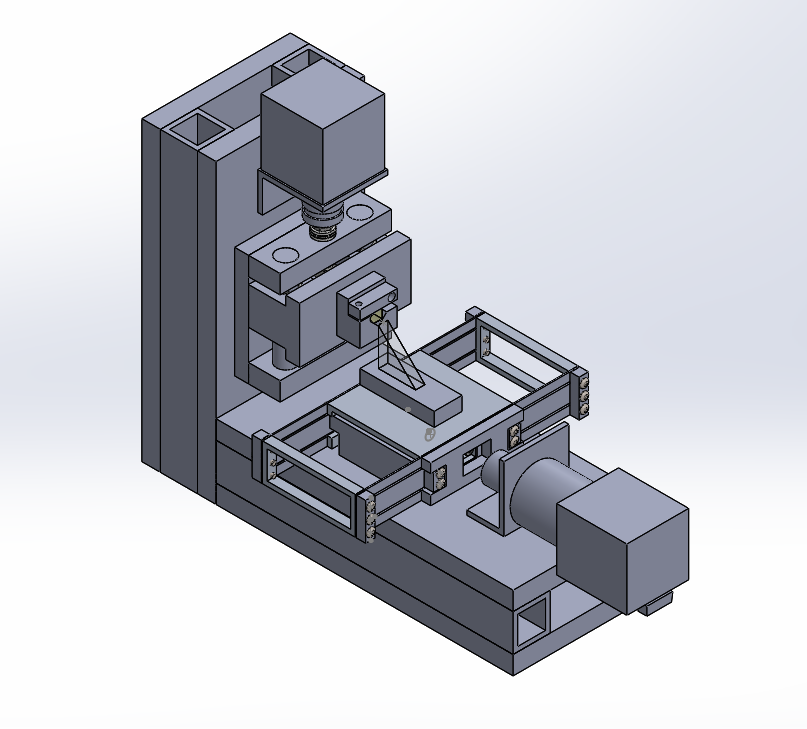

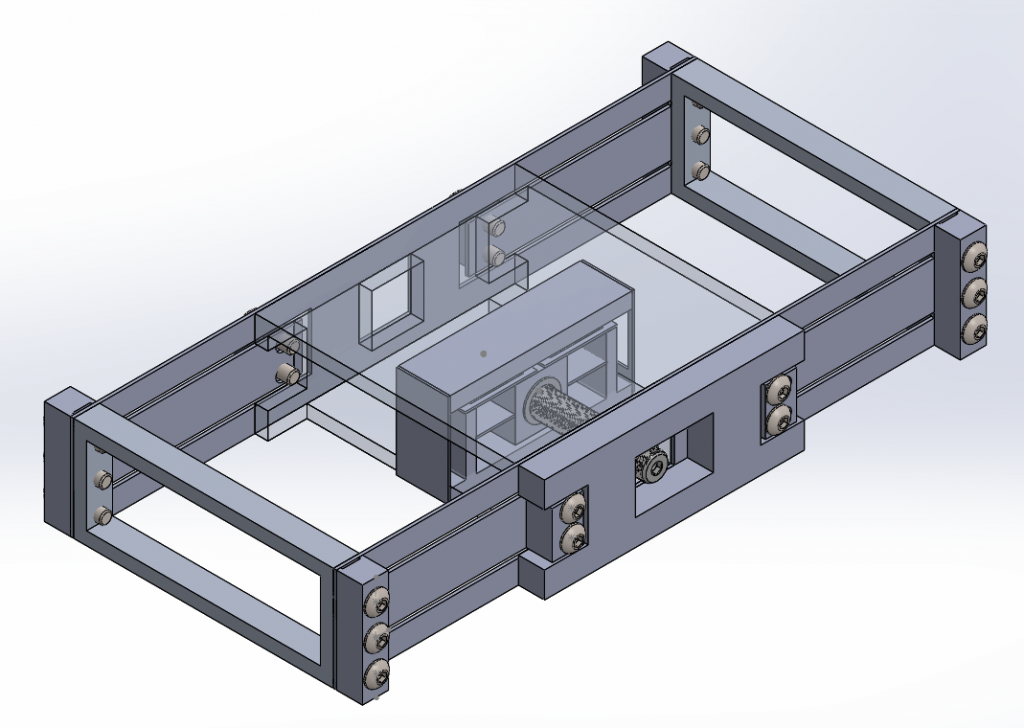

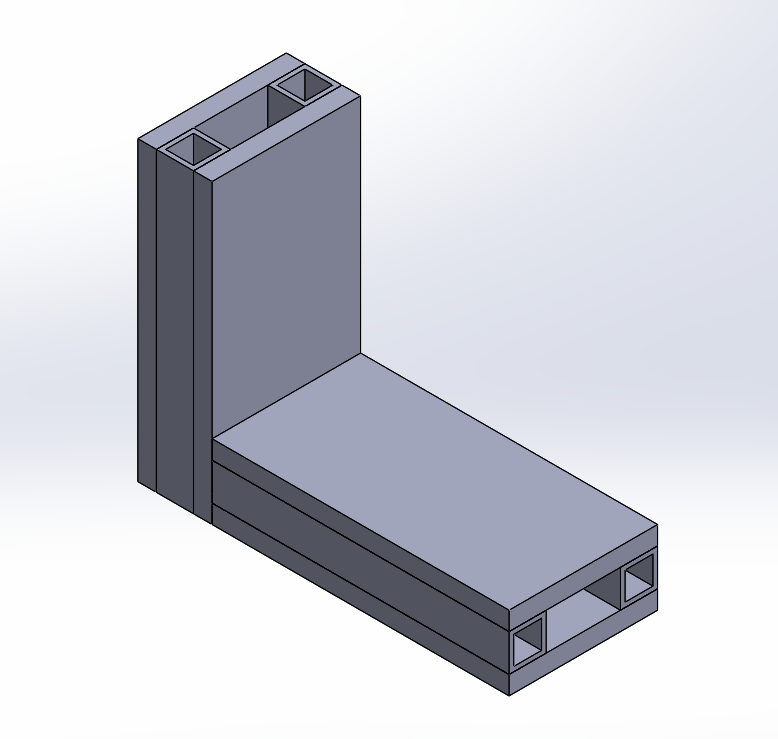

I designed the machine as three major modules – the X (feed) stage, Y (slice) stage, and Structure. Submodules include the X and Y built-up beams which comprise the structure, the knifeholder, and the specimen vise.

X stage

- Bearings

- Flexure

- Gearbox supports leadscrew thrust, radial (backlash?)

- Drive

- Stepper motor with 14:1 reduction couple to 1/4-80 leadscrew

- Decoupler

- Leadscrew drives X stage through decoupling nut (design in progress)

- Supporting worksheets

- x stage flexure design worksheet v1 – worksheet to design the main flexure bearing

- X decoupler flexure design worksheet v1 – worksheet to design the decoupler flexure

- X stepper motor and leadscrew reduction v1 – worksheet to calculate what resolutions I could get from a stepper motor

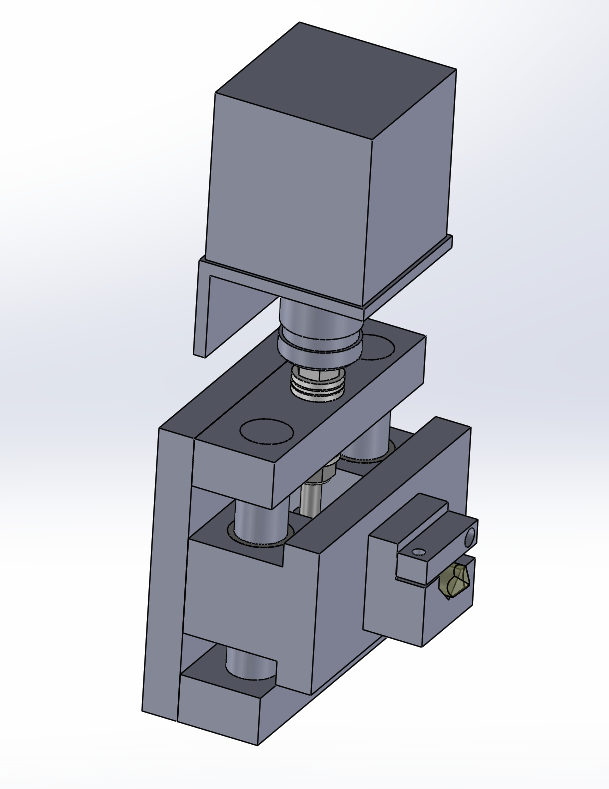

- Knifeholder

I’m working on a new concept for a knifeholder with high stiffness and large angle adjustment range based on line contact and planar kinematics (see video below…video worth a thousand words!). I need to figure out the details of preloading/stiffness/etc but the concept looks promising

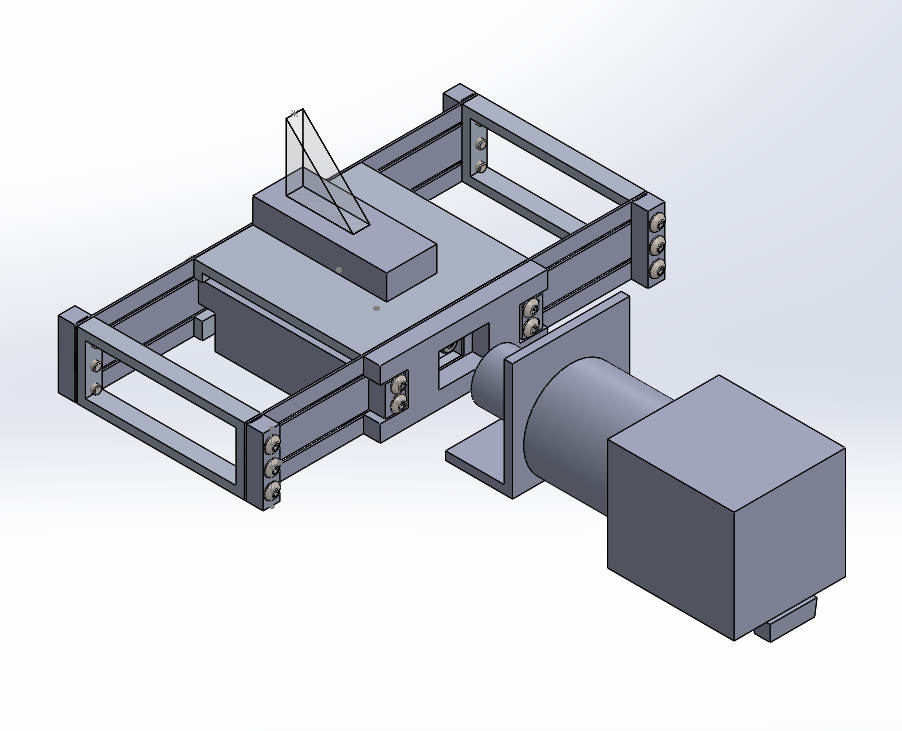

Y stage

- Bearings

- Two ball thrust bearings support the leadscrew’s thrust forces and one sleeve bearing supports it radially; other end unconstrained

- Drive

- Stepper motor with 10-32 leadscrew

- Decoupler

- Using the HeliCal coupling given to us

- Supporting calculations

- y axis leadscrew design v1 – various leadscrew-related calculations

- bushing linera stage stiffness – Used to calculate stiffness of a two-rod bushing stage and friction in the bushings

- ball slide stage stiffness – I used this to evaluate a stage concept that used balls

Structure

- Reinforcement – I would also like to have a gusset of some sort but I need to get back to the error budget and figure out how much stiffness I need from the structure

- Supporting worksheets: