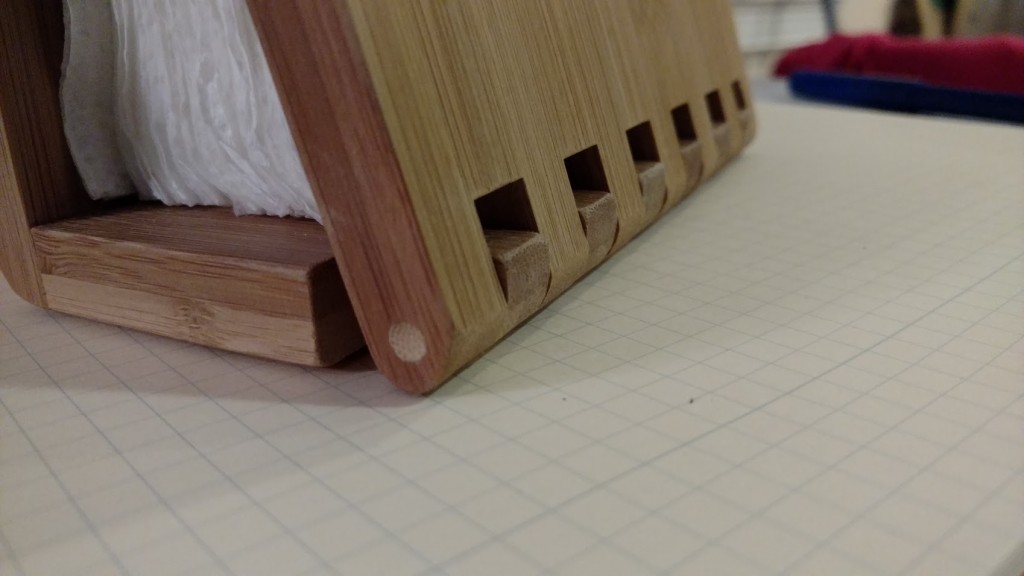

For this week’s Seek n’ Geek, I’m looking at a wooden napkin holder that relies on friction to hold napkins in place. In particular, I’m wondering how it can maintain it’s holding ability despite not having any sort of adjusting mechanism to tighten up the pivot. It also seems like a difficult manufacturing challenge to make these repeatably enough so that each napkin holder has just the right amount of friction – too loose and they flop over, too tight and they’re frustrating to use or they break.

The first thing I notice is that there’s no slop in the joint, I can’t wiggle it around at all. If I hold up the joints to the light, I can see gaps between some of the fingers – it looks like not all of the finger pairs have pins between them; the only fingers that I can see for sure that have pins are the leftmost and rightmost pair of fingers. The mechanism appears to loosen up as it approaches 45 degrees from the plane of the table, and then it tightens up again. What’s going on here?

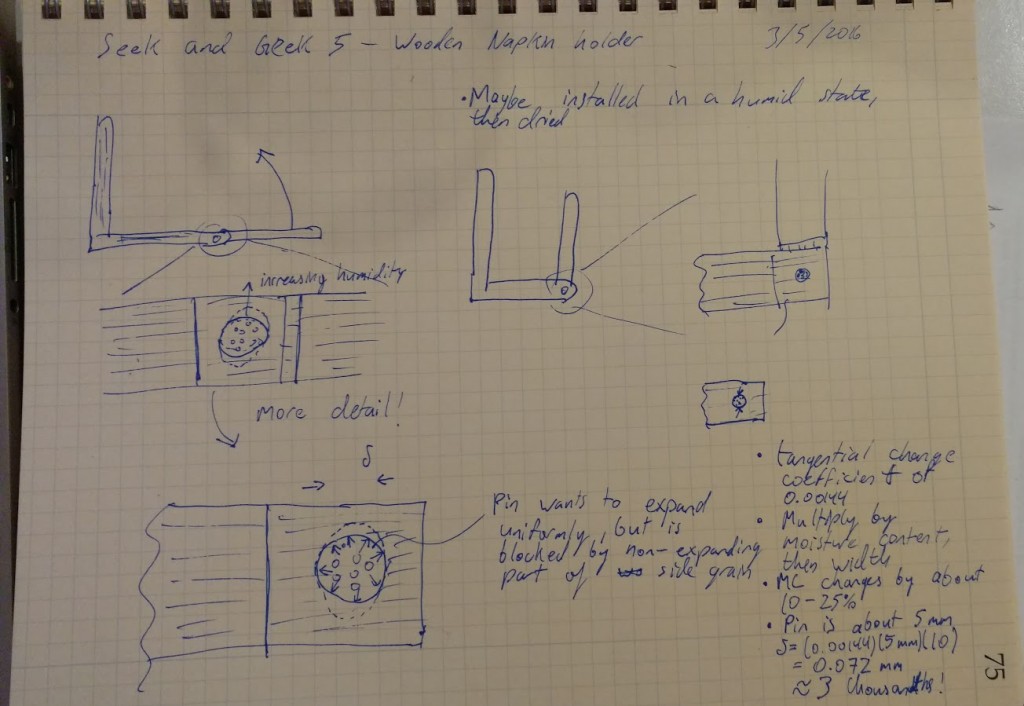

I can at least say that the direction-dependent properties of the wood don’t affect much here – since the grain of the wood is aligned, any expansion due to humidity change would affect both sets of fingers equally and there would be no net contraction or expansion. On the other hand, the pivot dowels are drilled and installed into side grain – the hole won’t expand uniformly

When I close the napkin holder, I can see that some of the fingers have gaps on both sides – there’s no engagement, and those fingers don’t contribute to the friction.

2 fingers have gaps on both sides, and 2 fingers have gaps on one side, so out of 12 possible contact surfaces, half are not in contact.

It seems that since there’s so many fingers it would be difficult to keep a tight enough control on the manufacturing process to keep the holders from being too tight or too lose – is there a more deterministic method that is being used to preload the pivot and provide friction?

Here’s one idea: the holders are manufactured and assembled in a very dry state; because the pivots are drilled into side grain, the side grain won’t expand uniformly and the pivot will preload itself against the hole upon reintroduction to a moist atmosphere

To test this hypothesis, I did an experiment – I held the napkin holder over a boiling kettle for a few minutes, and if my hypothesis was right, I should see the stiffness of the pivot increase. Sure enough, the swinging part was now more difficult to turn – it would no longer fall under its own weight, even when held horizontally!

I did some calculations to verify that this is feasible – I looked up the dimensional change coefficient of bamboo, and assumed that the moisture content increased by about 10% from when it was made and when it was being used. This results in the pivot dowel being pinched by about 75 microns, or 0.003 inches! That seems about right.

I did a brief search online but couldn’t find any information about whether or not this is how these are designed to be made! I’m very curious now, so if anyone knows for certain I’d be happy to hear about it!